Sewing Machine Not Sewing ?

7 Most Common Reasons and How to Fix Them

Everything looks ready — the fabric is under the presser foot, the thread is in place, you press the pedal… and nothing happens. No stitches, no movement. What went wrong?

Before you panic, let me say this: some of the reasons might sound obvious, like “check the threading” or “look at the needle,” but after 20 years as a sewing machine mechanic, I can tell you — these small details are what cause most problems, even for experienced sewists.

⚠️ I often have customers bringing machines to my workshop, convinced that the motor is dead or something major broke. And you know what? In many cases, I simply re-thread the top thread — it was sitting next to, not between, the tension discs. I fix it, and the machine sews perfectly again. That’s the whole “repair.”

📌 So don’t worry. After reading this article:

– You’ll solve about 50% of issues yourself,

– You’ll understand what’s happening inside your machine,

– And you’ll be able to talk to a mechanic confidently — knowing what you’re paying for.

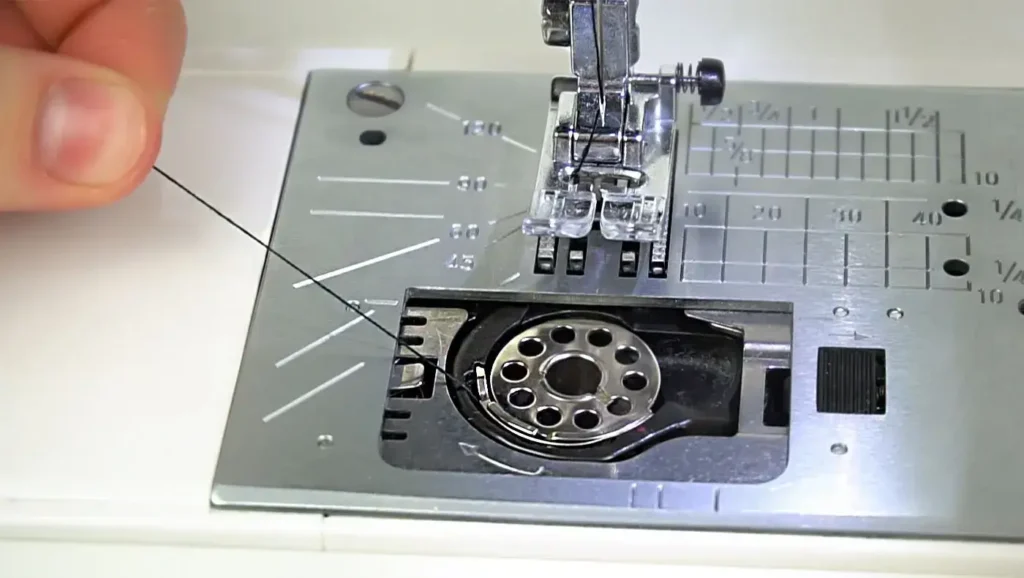

1. Incorrect Threading

This is the most common reason your sewing machine won’t sew.

This is the most common reason your sewing machine won’t sew.

If the thread didn’t go through the tension discs properly, twisted, or missed a guide — the stitches won’t form.

✅ Check:

-

Is the upper thread correctly placed between the tension discs?

-

Is the bobbin case properly installed?

-

Is the thread in the bobbin moving freely?

📌 Mechanic’s tip: Remove both threads and re-thread the machine carefully from scratch. It solves the issue surprisingly often.

👉 Watch my threading guide →

2. Needle Inserted Incorrectly or Dull

A needle that’s slightly bent, dull, or not pushed all the way in can cause skipped stitches or prevent the hook from catching the loop.

✅ Check:

-

Is the needle straight and fully inserted?

-

Is the flat side facing the right direction (usually back)?

-

Is the needle suitable for the fabric you’re sewing?

📌 Mechanic’s tip: Even if the needle “looks fine,” replace it with a new one.

It’s the cheapest fix for half of all sewing problems.

🎥 On my Facebook page you’ll find videos where I show how the needle and hook should work together — both on horizontal and vertical hook systems.

👉 Watch the video →

👉 Recommended sewing needles →

3. Hook Not Catching the Thread

If the needle moves but no stitches form, it means the hook isn’t catching the loop.

This can happen when the needle is installed too high or the timing is off.

✅ Check:

Does the handwheel turn smoothly?

Does the needle reach the correct depth?

Is the bobbin case staying in place?

📌 Mechanic’s tip: If the needle touches the hook or the loop doesn’t form at all, it’s time for a timing adjustment.

👉 Watch how the hook works →

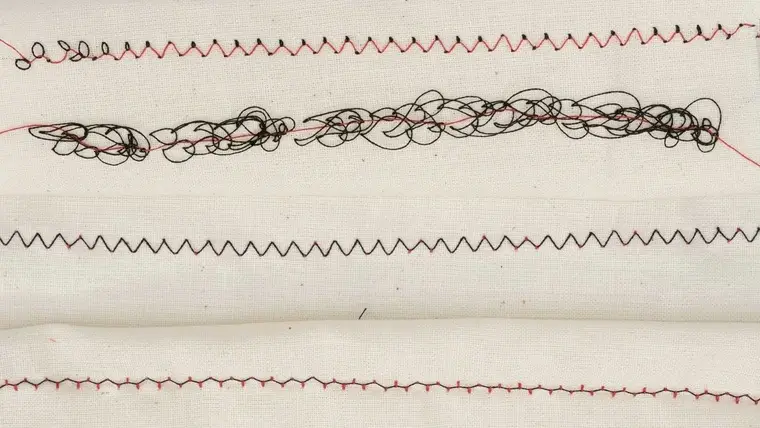

4. Loops, Skipped Stitches, or Uneven Sewing

If your stitches look messy, like a “bird’s nest” or zig-zag pattern, the problem is often with the needle or thread quality.

✅ Check:

-

What type of thread are you using?

-

Is it matched to the fabric?

-

Are the upper and lower tensions balanced?

📌 Mechanic’s tip: Don’t use old cotton thread — it breaks easily, leaves lint, and clogs the hook area.

👉 Best threads for home sewing machines →

5. Machine Is Dirty Inside

Dust, lint, and thread bits build up over time — especially if you sew fleece, jersey, or minky.

When the hook or feed dogs are full of lint, the machine can’t move the fabric properly.

✅ Check:

-

Is the hook area clean?

-

Are the feed dogs free of debris?

📌 Mechanic’s tip: Clean first, oil later. Never add oil on top of lint.

👉 How to clean and oil your machine →

6. Machine Doesn’t Respond — Motor or Foot Pedal Issue

If the machine doesn’t run at all — no sound, no movement — the problem may be with the power cord, foot pedal, or motor.

✅ Check:

-

Is the plug fully inserted?

-

Does the pedal click or hum when pressed?

-

Do you smell anything burning?

📌 Mechanic’s tip: If the machine is silent — unplug it and stop trying. Continuing could cause more damage.

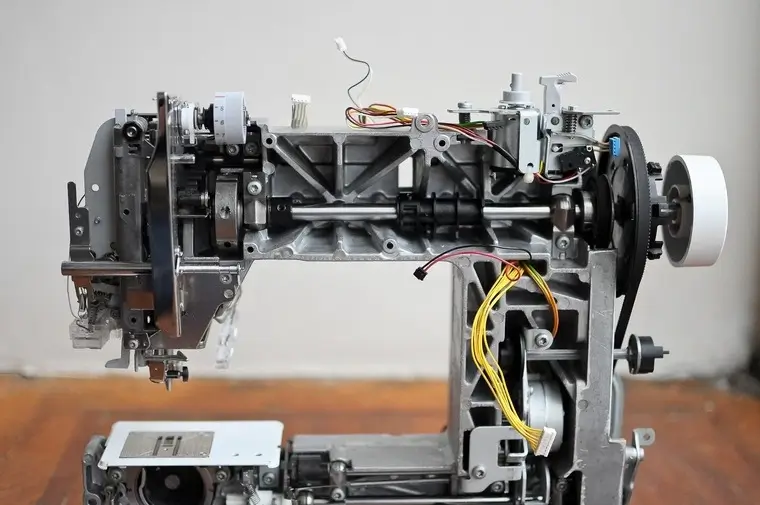

7. Worn or Broken Internal Parts

After years of use, plastic gears, shafts, and bushings can wear out.

This is common in older or heavily used machines.

✅ Check:

-

Does the handwheel spin freely but the needle doesn’t move?

-

Do you hear clicks, grinding, or knocking?

-

Does the machine jam frequently?

📌 Mechanic’s tip: If you hear grinding or clicking, don’t just add oil blindly. Find out what’s actually broken first.

👉 Contact me for diagnosis →

Sewing Machine Not Sewing?What If Nothing Helps?

If you’ve checked everything and your machine still won’t sew — don’t worry.

You’ve already done half of what a professional mechanic would do.

Now you understand where the issue might be and can talk to a technician with confidence — saving both time and money.

At SewingSage Studio, I share my 20+ years of experience to help you sew smarter, fix better, and enjoy your machine longer.

Keep learning, stay patient — and remember, even the best machines need a little care sometimes.

Useful Links

👉 Best threads for home sewing machines – full guide

👉 How to choose the right needle for your fabric

👉 Download my free Sewing Accessories PDF →

Stay Connected and Learn More

If this article helped you — share it and follow my channels for more free advice, videos, and practical guides.

📸 Facebook | YouTube | Instagram | TikTok